Fantasize creating your own electrical masterpiece? Or perhaps you're just keenly curious about how that shiny copper busbar in your electrical panel came into being? Either way, breaking down the process of m![]() aking a copper busbar should add sparks to your electrical knowledge!

aking a copper busbar should add sparks to your electrical knowledge!

Understanding Copper Busbars

Copper busbars, with their exceptional conductivity and durability, are the power highways of our electrical systems. But how does one go from raw copper to a sophisticated busbar? Strap in, folks! We're about to embark on an enlightening journey.

Creating a copper busbar requires meticulousness, proper tools, and, most importantly, diligence for safety standards. Before diving into this adventure, remember, safety is paramount! So put on your safety gears and get ready to roll.

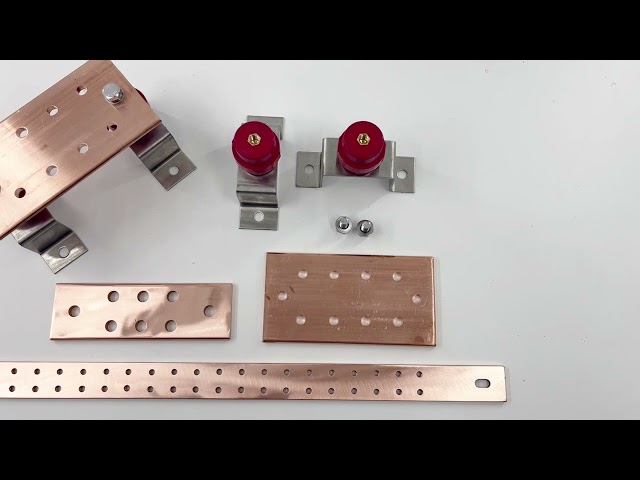

The process initiates with choosing a quality copper sheet, having a thickness ranging typically from 1/8 to 1/4 inches. The sheet's thickness will attest to the busbar's current-carrying capacity.

Once the sheet is selected, the copper must be precisely measured, marked, and cut according to the desired busbar dimensions. A saw, specifically for metal cutting, is usually used for this task. But remember, accuracy is key!

Next, is the shaping part. Ever heard of a 'busbar bending machine'? If not, it's about to become your new best friend. A busbar bending machine is specifically designed to give your copper busbar the perfect bends without cracking or breaking it.

Post-bending, it's time to pierce holes into the busbar. But why holes, you ask? Well, these are the points where your busbar will connect with other electrical components. A power drill along with cobalt drill bits is typically used for this process.

Lastly, comes cleaning and polishing - because who doesn't like a shiny, smooth busbar, right?

Always remember - during the whole process, keeping safety measures and wearing protective gear is vital to prevent any mishaps.

Undertaking a DIY copper busbar creation should always be done under the guidance of an expert or with a sound knowledge of electrical components and practices. While the process might be relatively simple when laid out in steps, there's no room for shortcuts or compromises when it comes to safety!

The adventure from raw copper to a busbar is indeed fascinating! But is making a copper busbar a feasible DIY project? Truthfully, while it's possible, it's recommended only for those with a deep understanding of electrical components, access to correct tools, most importantly a busbar bending machine, and an unwavering adherence to safety measures.

Isn't it remarkable how shared knowledge makes us appreciate even mundane things around us? Who knew that the creation of a copper busbar would resemble a well-choreographed ballet, tweaking, tuning, bending and twisting? Makes you look at your copper busbar in a whole new light, right?

Comments