Revolutionary Electron Beam Uses in Modern Tech

The rapid advancements in technology continue to amaze us with their transformative impact on industries, enhancing production capabilities and driving unprecedented levels of innovation. A prime example of such groundbreaking progress is Essential Electron Beam Applications. Initially developed for research and specialized scientific purposes, electron beams (e-beams) have grown significantly in relevance across various fields, spanning material science, electronics, and even medicine. This article explores the revolutionary applications of electron beams, highlighting how they are reshaping industries and pushing the boundaries of what's achievable.

1. Understanding Electron Beam Technology

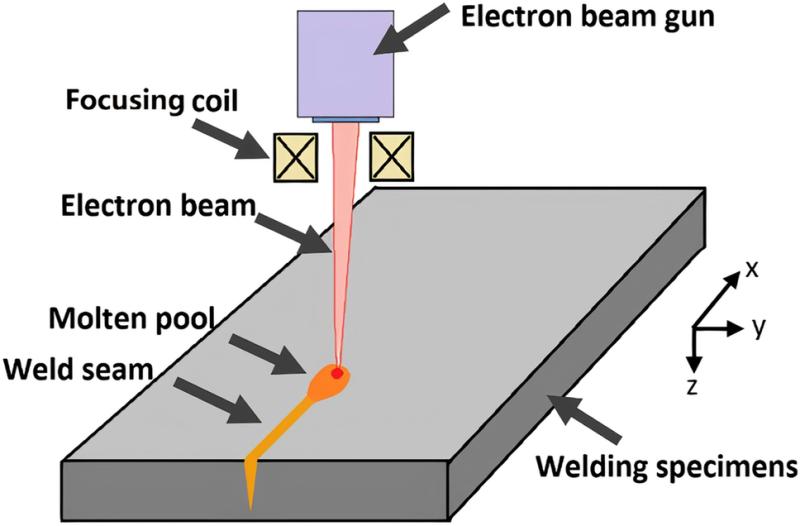

An electron beam is a stream of electrons directed at a high velocity toward a specific target or material. These beams are produced by electron guns, which generate and accelerate electrons in a vacuum chamber. When these accelerated electrons strike a target material, they release energy in the form of heat, radiation, or secondary electrons, depending on the interaction and material properties. The controllability and precision of e-beams make them ideal for high-precision applications across a wide range of industries.

2. Revolutionizing Manufacturing through E-Beam Welding

One of the most well-known uses of electron beams is in welding. E-beam welding is a highly effective, precise method of joining materials, especially metals, by focusing an electron beam on the area where the pieces meet. The concentrated energy melts the material at the joint, creating a strong bond without the need for filler materials or flux.

High Precision and Speed: The intensity of electron beams allows them to weld metals with high precision and at an incredibly fast rate. This is invaluable in industries like aerospace, automotive, and defense, where strong, lightweight materials are critical, and even the slightest imperfection can lead to failure.

Welding Dissimilar Metals: Another significant advantage is the ability to join dissimilar metals, which is challenging with traditional welding techniques. This is particularly useful for creating custom metal alloys in industries where specialized material properties are needed.

Reduced Contamination: Electron beam welding occurs in a vacuum, which means there’s minimal risk of contamination from the atmosphere. This results in cleaner, stronger welds, especially important in high-stakes applications like nuclear reactors or space exploration.

3. Electron Beams in Semiconductor Fabrication

The electronics industry has also benefited tremendously from electron beam technology, especially in semiconductor manufacturing. Semiconductor chips, which power almost all modern devices, are created through a process called lithography, where specific patterns are etched onto silicon wafers to create integrated circuits. Electron beam lithography (EBL) offers high precision in creating these patterns, making it indispensable in producing the tiniest components on microchips.

Higher Resolution and Precision: EBL is capable of achieving resolutions as small as a few nanometers, which is far beyond the capabilities of traditional photolithography. This level of precision is necessary as electronics become smaller and more powerful, with components that need to be packed onto tiny chips.

Maskless Lithography: Unlike photolithography, which requires masks for each pattern, EBL is a maskless process. This flexibility enables manufacturers to prototype new designs quickly, reducing development times and costs for experimental chips.

Future of Nanoelectronics: EBL is expected to play a crucial role as the electronics industry moves toward nanoelectronics, a field focused on creating devices and circuits on an atomic or molecular scale. The demand for smaller, faster, and more energy-efficient chips makes electron beam technology an essential tool in driving innovation.

4. Electron Beam Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, has been a disruptive technology in its own right. Electron beam additive manufacturing (EBAM) is an advanced form of 3D printing that uses an electron beam to melt metal powders or wire into specific shapes. This process offers several advantages over traditional manufacturing techniques.

Efficient Production of Large Metal Parts: EBAM can produce large, complex metal parts with minimal material wastage, a feature particularly valuable in aerospace and automotive manufacturing. For instance, producing aircraft components requires robust, lightweight parts that can withstand intense mechanical stress, and EBAM offers a viable way to create these with high precision and strength.

Reduced Production Time: EBAM is capable of building metal parts faster than traditional methods, as it does not require molds or casting. This speed not only reduces production costs but also supports on-demand manufacturing for critical industries, cutting down on lead times significantly.

Potential for Recycling Materials: In some applications, EBAM enables manufacturers to recycle scrap metal, reducing waste and promoting sustainable production practices. This recycling capability aligns with broader efforts to make industrial manufacturing more eco-friendly.

5. Sterilization in Medical and Food Industries

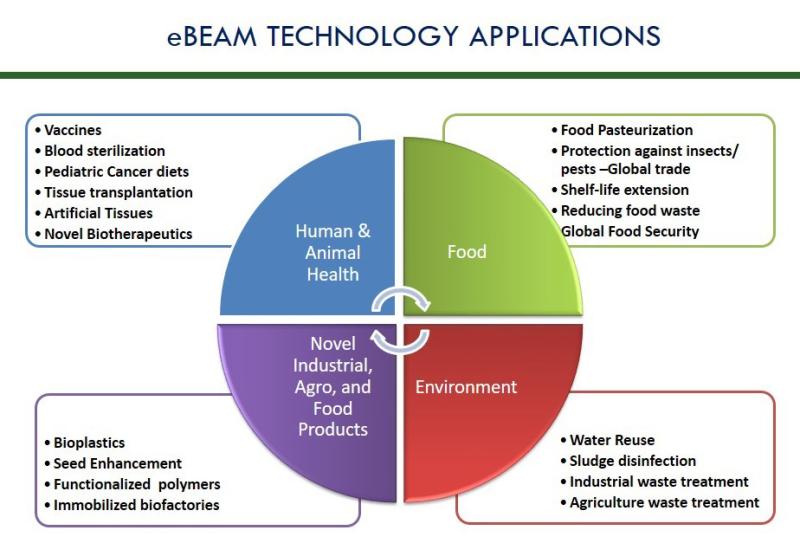

Another remarkable application of Essential Electron Beam Applications is in sterilization. E-beam sterilization has gained popularity in the medical and food industries, where eliminating pathogens and ensuring product safety is critical.

Effective and Quick Sterilization: Electron beams can kill bacteria, viruses, and other pathogens quickly without the need for chemicals or high temperatures. This is especially useful for sterilizing single-use medical devices like syringes, implants, and surgical instruments.

Preservation of Product Integrity: Since e-beam sterilization is a non-thermal process, it’s suitable for products that could be damaged by heat. For instance, food products can be sterilized without altering their taste, texture, or nutritional value, a significant advantage over other preservation methods.

Eco-Friendly Alternative to Chemical Sterilization: Traditional sterilization methods often rely on chemicals that can be harmful to the environment. E-beam technology provides a cleaner, safer option, reducing reliance on these potentially toxic substances.

6. Future Prospects and Innovations with Electron Beams

As the uses for electron beam technology expand, researchers and engineers are discovering even more potential applications. Future innovations in e-beam technology are expected to enhance its use in fields such as:

Nanotechnology and Materials Science: The precision and high-energy nature of electron beams make them ideal for altering materials at an atomic level. This could lead to breakthroughs in developing new materials with unique properties for applications in electronics, medicine, and energy storage.

Energy Production: Electron beam technology is being researched for potential applications in sustainable energy. By using e-beams to alter material properties or catalyze reactions, scientists are exploring ways to make renewable energy sources more efficient and affordable.

Environmental Applications: E-beam technology has promising uses in environmental protection, such as treating industrial wastewater or reducing emissions from factories. Electron beams can break down hazardous pollutants, turning them into harmless compounds, which could be a game-changer in reducing pollution.

Conclusion

Electron beam technology has undoubtedly made a revolutionary impact across various industries, pushing the boundaries of modern manufacturing, electronics, and healthcare. Its precision, speed, and versatility have established it as a cornerstone of cutting-edge applications in fields that demand both innovation and accuracy. As research and development continue, we can expect electron beam technology to drive new breakthroughs that will shape the future of technology and industry, bringing us closer to solutions for complex challenges in manufacturing, medicine, and environmental sustainability.