Is a CNC Fiber Laser Cutting Machine Right for You?

CNC fiber laser cutting technology is a highly efficient way for material processing, employing focused laser beams to form exact cuts in diverse materials like metals, plastics, and composites. It employs fiber optics to supply high-intensity laser light, leading to higher cutting rates and low thermal distortion. This automation is a popular option in sectors like manufacturing, aircraft, and automobiles since it guarantees constant quality and increases efficiency. However, maximizing operational productivity and cost-effectiveness requires assessing the technology's applicability and applications. Considerations include things like manufacturing volume, thickness, and material kind.

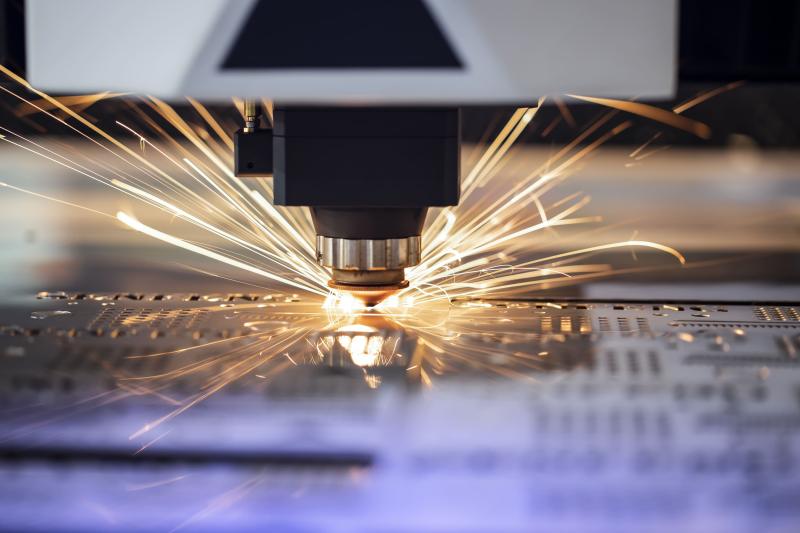

Understanding CNC Fiber Laser Cutting

A powerful beam is employed by CNC fiber laser cutting equipment to cut materials exactly. By magnifying light and focusing it through a lens onto the workpiece, a fiber optic cable produces the laser. The fabric is melted or vaporized by this concentrated laser, enabling complex patterns and structures. A computer numerical control (CNC) system operates the machine, deciphering design files and converting them into accurate laser head motions. The cutting head, motion system, CNC system, and laser source are essential parts of CNC fiber laser cutting machines. Usually, a fiber laser, which is renowned for its durability and efficiency, is the laser source. Complex programming and automation are made possible by the CNC system, which oversees the machine's operation.

Advantages of CNC Fiber Laser Cutting Machines

Compared to standard techniques, a CNC Fiber Laser Cutting Machine provides speed, accuracy, and precision, which makes them perfect for fine details. They will cut a spread of materials, including metals, polymers, and composites, and are quicker, simpler, and more adaptable. Due to their capacity to lower production costs and times, they're a top option in contemporary manufacturing.

Applications of CNC Fiber Laser Cutting

Because of its accuracy and effectiveness, CNC fiber laser cutting technology is widely employed in sectors including metal production, electronics, automotive, and aerospace. It's perfect for creating complicated parts like brackets and chassis pieces because it allows for high-speed processing and elaborate patterns. This system is employed within the aerospace sector for lightweight structural elements that require to be very precise and waste as little material as possible.

Cost Considerations

From tens of thousands to many hundred thousand dollars, purchasing CNC fiber laser cutting equipment is often expensive. On the opposite hand, the long-term savings from lower labor expenses, energy use, and material waste might end in a positive return on investment. Companies that use this technology could anticipate shorter manufacturing times, which can boost their bottom line. A Laser Cutting Machine manufacturer is important for supplying leading-edge technology in sectors including manufacturing, aircraft, and automobiles. These devices enhance production operations by enabling complex patterns and superior cutting with less material loss.

Material Compatibility

Fiber laser cutting works well for cutting non-metals like wood and plastics, as well as metals like brass, aluminum, and chrome steel. Reflective metals, like brass and copper, can obstruct the cutting process, though. When utilizing fiber laser cutting technology, operators must take these restrictions under consideration and do comprehensive material examinations to ensure the simplest possible outcomes.

Maintenance and Support

For CNC fiber laser cutting equipment to work well and last an extended time, regular maintenance is important. Inspections, lens cleaning, and cutting head calibration are important duties. Troubleshooting and fixing such problems requires keeping an eye on the cooling system and offering professional assistance. Thorough operator training increases productivity and reduces downtime by improving the operator's comprehension of the machine's capabilities and maintenance needs.

Comparing CNC Fiber Laser Cutting to Other Cutting Technologies

In terms of accuracy, speed, and thickness, CNC fiber laser cutting technology performs better than conventional techniques like water jet cutting, plasma cutting, and other conventional techniques. It's perfect for delicate patterns since it creates finer details and cleaner edges. Water jet cutting is quicker but slower and more costly than plasma cutting, which is rougher but less effective on thinner materials. Infrastructure is important to ensure safety, dependability, and scalability when integrating laser cutting and welding technologies into industrial operations. A robust laser cutting and welding infrastructure makes it easier to put in automation, train operators, and perform maintenance, which boosts output and competitiveness within the market.

Assessing Your Specific Needs

Think about your production volume, project complexity, and, therefore, the kinds and thickness of materials you would like to chop when choosing a CNC fiber laser cutting equipment. Inquire about the training level, maintenance, support, and total cost of ownership to form an informed choice that's suited to your particular operating requirements.

Conclusion

Although CNC fiber laser cutting technology is fast, precise, and versatile, it must be carefully assessed to match operational objectives. Organizations will improve their production capacities and acquire a competitive edge in the market by taking these elements under consideration when making decisions about their implementation.

Comments