How CNC Fiber Laser Cutting Machines Are Revolutionizing the Sheet Metal Industry

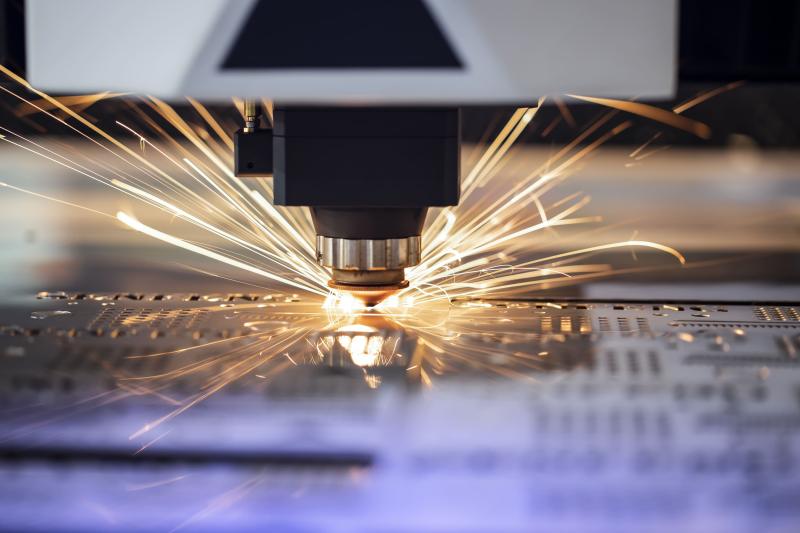

The sheet metal industry has undergone a significant transformation with the introduction of advanced technologies. Among these innovations, the CNC Fiber Laser Cutting Machine stands out as a game-changer. Its ability to deliver precision, speed, and efficiency has made it a preferred choice for manufacturers. Here’s how these machines are revolutionizing the sheet metal industry.

Versatility with Materials

CNC fiber laser cutting machines are versatile when it comes to materials. They can cut through various types of metals, including stainless steel, aluminum, brass, and copper. This versatility makes them ideal for the sheet metal industry. Manufacturers often deal with different types of materials.

Traditional cutting tools may struggle with certain metals. But CNC fiber lasers provide consistent results across a wide range of materials. This adaptability has made them popular in industries.

Precision at Its Best

One of the biggest advantages of using a CNC Fiber Laser Cutting Machine is its precision. The laser beam (used in these machines) cuts through sheet metal with exceptional accuracy. It is challenging to attain this degree of precision with conventional cutting techniques. As a result, manufacturers can produce intricate designs and complex components with ease.

The accuracy of CNC fiber lasers also reduces material waste. Each cut is clean and precise. They leave no rough edges or unnecessary material loss. This is especially important in industries like automotive, aerospace, and electronics, where every millimeter counts.

Faster Production Times

Speed is another area where CNC fiber laser machines excel. They cut through sheet metal much faster than conventional methods. This speed leads to higher production rates. It helps manufacturers meet tight deadlines. Whether it’s a small job or large-scale production, these machines can handle the workload efficiently.

For businesses, faster production means improved turnaround times. Orders can be completed quickly. It allows companies to take on more projects and increase profitability. This has made CNC fiber laser machines a must-have for companies looking to stay competitive in the market.

Reduced Labor Costs

The automation provided by CNC fiber laser cutting machines helps reduce labor costs. Once trained, these machines require very little assistance from humans. Operators can set up the machine, input the specifications, and let it run independently.

This automation allows manufacturers to reduce the number of workers. It also reduces the chances of human error, ensuring that each cut is perfect. In the long run, businesses save money on labor while increasing production efficiency.

Non-Contact Cutting for Durability

CNC fiber laser cutting machines offer non-contact cutting. This reduces the risk of wear and tear on the machine itself, making it more durable and long-lasting. Moreover, non-contact cutting minimizes damage to the material being processed. There’s no distortion or warping, even when working with thin or delicate metals.

Integration with Welding Capabilities

Many laser cutting machine manufacturers are now offering machines that combine cutting and welding capabilities. This integrated approach creates a seamless workflow for companies that require both functions in their production process. By utilizing laser cutting and welding infrastructure, manufacturers can streamline operations, saving time and resources.

The integration of cutting and welding in one machine eliminates the need for separate equipment. This not only saves space on the production floor but also reduces costs associated with maintaining multiple machines. The end result is a more efficient manufacturing process.

Safety and Reduced Risk

Safety is always a concern in manufacturing environments. Since the machines operate with minimal human interaction, the risk of accidents is lower. CNC Laser Cutting Machine manufacturers have designed them with safety in mind. Most machines also come with enclosed systems. It protects workers from exposure to the laser beam.

This focus on safety not only protects workers but also ensures that companies can operate without interruption. There are fewer accidents in a safe working environment. It raises total productivity and decreases downtime.

Consistent Quality

Consistency is key in the sheet metal industry. Every piece of metal needs to meet strict quality standards. CNC fiber laser cutting machines deliver consistent results every time. Whether it’s the first cut or the hundredth, the quality remains the same.

This consistency helps manufacturers maintain a high level of quality control. Products that require precise measurements and specifications benefit greatly from the accuracy and reliability of CNC fiber lasers.

Environmentally Friendly Operation

CNC fiber laser cutting machines are also more energy-efficient compared to older cutting technologies. They use less power while delivering better results. They are therefore a more eco-friendly choice for producers trying to lower their carbon footprint.

Additionally, the precision of these machines reduces waste, further contributing to their eco-friendliness. By using CNC fiber lasers, companies can achieve sustainability goals without sacrificing performance.

Conclusion

The sheet metal industry has seen massive benefits from the adoption of CNC fiber laser cutting machines. Their precision, speed, and versatility have transformed how manufacturers approach production. With reduced costs, improved safety, and consistent quality, it’s no surprise that these machines are becoming the industry standard. Whether for small projects or large-scale production, CNC fiber laser cutting machines continue to shape the future of sheet metal manufacturing.

Comments