Revolutionizing Efficiency: The Latest Innovations in Industrial Power Tool

The industrial power tools market is undergoing a revolution in 2024, driven by rapid advancements in technology, increased demand for efficiency, and the need for environmentally sustainable solutions. As industries like construction, manufacturing, and automotive continue to evolve, so too must the tools used to perform key tasks. Industrial power tools are critical for increasing productivity, improving safety, and reducing manual labor in these fields. This article explores the latest innovations in industrial power tools that are set to redefine efficiency and performance in 2024.

The Growing Importance of Industrial Power Tools

Power tools have long been essential in industrial settings, but 2024 marks a new era of innovation. With rising labor costs, the need for precision, and sustainability pressures, companies are seeking out advanced power tools that offer superior performance, reduced energy consumption, and enhanced safety features. The global market for industrial power tools is expected to see substantial growth, driven by these factors, along with a surge in infrastructure projects and automation.

1. Cordless Technology: Enhanced Mobility and Efficiency

One of the biggest trends in 2024 is the dominance of cordless power tools. The transition from traditional corded tools to cordless models has been gaining momentum for several years, but 2024 is expected to witness a significant leap in battery technology. With advancements in lithium-ion batteries, cordless tools now provide longer runtime, quicker charging times, and more power. This not only improves mobility and convenience on job sites but also reduces downtime associated with cord management and power supply issues.

2. Brushless Motors: Higher Efficiency and Durability

Brushless motor technology is another game-changing innovation in industrial power tools. These motors generate less friction, resulting in cooler operation and increased tool life. In 2024, more power tools are expected to adopt brushless motors, offering higher efficiency and improved performance. The key benefits include reduced maintenance, greater power output, and longer battery life in cordless tools. This technology is particularly beneficial for heavy-duty applications in industries such as construction, metalworking, and manufacturing, where tools are subjected to high levels of wear and tear.

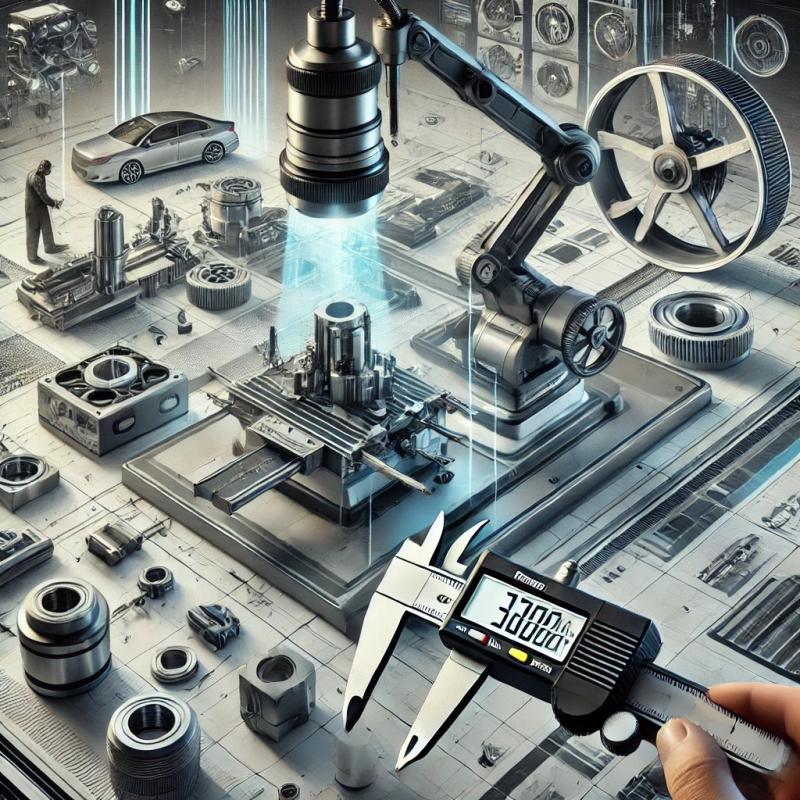

3. Smart Power Tools: Integrating IoT and AI for Enhanced Precision

The integration of the Internet of Things (IoT) and artificial intelligence (AI) is revolutionizing the industrial power tool landscape. In 2024, smart tools that connect to mobile devices and cloud platforms are becoming more common. These tools are equipped with sensors that monitor performance, provide real-time feedback, and optimize tool settings for specific tasks. For example, smart drills can automatically adjust torque and speed based on the material being worked on, ensuring optimal performance and precision. These innovations reduce errors, increase safety, and improve overall job site efficiency.

4. 3D Printing in Power Tool Production: Customization and Speed

Another significant innovation is the use of 3D printing technology in the production of industrial power tools. In 2024, manufacturers are increasingly adopting 3D printing to create custom tool components and parts that are tailored to specific applications. This allows for greater customization, faster production times, and lower costs. Moreover, 3D-printed parts are often lighter and stronger than traditionally manufactured components, enhancing the durability and ergonomics of power tools.

5. Sustainable and Eco-Friendly Power Tools

As industries strive to reduce their carbon footprint, sustainability is a key focus in the development of new power tools. In 2024, more manufacturers are offering eco-friendly power tools that use sustainable materials, energy-efficient batteries, and recyclable components. Companies are also focusing on reducing noise and vibration levels, making tools not only more environmentally friendly but also safer and more comfortable for operators. Sustainable power tools are designed to have a longer lifespan, which contributes to waste reduction in industrial environments.

6. Automated Tool Systems for Increased Productivity

Automation is transforming industrial workflows, and power tools are no exception. In 2024, automated tool systems are gaining traction, allowing for hands-free or semi-automated operation. For example, robotic arms equipped with power tools can perform repetitive tasks with high precision, reducing human error and increasing productivity. These systems are particularly useful in assembly lines, automotive manufacturing, and precision metalworking, where consistent, high-quality results are essential.

7. Ergonomic Designs: Improving Operator Comfort and Safety

In 2024, ergonomic design is a top priority for industrial power tool manufacturers. With a growing focus on worker health and safety, tools are being designed to minimize strain, reduce the risk of injury, and enhance user comfort. Lighter materials, balanced weight distribution, and vibration-dampening features are becoming standard in new power tools. This is particularly important for industries like construction and manufacturing, where workers often use power tools for extended periods, leading to potential fatigue and injury.

8. Multi-Function Tools: Versatility for Diverse Applications

The demand for versatile tools that can handle multiple tasks is on the rise in 2024. Multi-function power tools, which combine several functions into one unit, are becoming increasingly popular. For example, a single tool might serve as a drill, driver, and impact wrench, allowing workers to switch between tasks without needing to change tools. This innovation saves time, reduces the number of tools needed on job sites, and enhances overall efficiency.

9. Advanced Safety Features: Prioritizing Worker Protection

Safety remains a top concern in industrial environments, and 2024 has seen the introduction of power tools with enhanced safety features. Innovations such as automatic shut-off mechanisms, overload protection, and anti-kickback systems are becoming more widespread. Additionally, tools are being equipped with sensors that detect potential hazards, such as overheating or excessive vibration, and automatically adjust their operation to prevent accidents. These features contribute to a safer working environment and reduce the risk of injury.

10. Energy-Efficient Tools: Reducing Operational Costs

Energy efficiency is a major focus for industrial power tools in 2024. As industries look to reduce operational costs and environmental impact, manufacturers are developing tools that consume less energy while maintaining high performance. Energy-efficient motors, improved battery technology, and advanced control systems are key innovations driving this trend. These tools not only reduce energy consumption but also contribute to lower operational costs and longer tool lifespans.

Key Industry Sectors Adopting Advanced Power Tools

Several key industry sectors are leading the adoption of advanced power tools in 2024:

1. Construction

The construction industry relies heavily on power tools for tasks ranging from demolition to finishing work. The shift toward cordless, smart, and multi-function tools is helping construction workers complete tasks more efficiently while reducing manual labor.

2. Automotive Manufacturing

In automotive manufacturing, precision and consistency are critical. Smart power tools and automated systems are being used to streamline production processes, improve accuracy, and reduce defects.

3. Metalworking

Metalworking industries are benefiting from the use of brushless motors, 3D-printed components, and energy-efficient tools that can handle high-stress applications with ease.

4. Energy and Utilities

Energy-efficient power tools are increasingly being adopted in the energy and utilities sectors, where they contribute to cost savings and environmental sustainability.

Conclusion

The industrial power tools market is set for significant growth and transformation in 2024, with innovations that are revolutionizing efficiency, safety, and sustainability. From the rise of cordless tools and brushless motors to the integration of IoT and AI, these advancements are reshaping how industries operate. As companies continue to seek ways to improve productivity, reduce operational costs, and enhance worker safety, the latest generation of industrial power tools will play a crucial role in meeting these goals. Whether you’re in construction, manufacturing, or any other industry that relies on power tools, staying updated with these innovations will be essential for staying competitive in 2024 and beyond.

Comments