The Advance of China Metal Spinning Service

Metal spinning, also known as spin forming or metal spinning, is a manufacturing process that involves the shaping of metal sheets or tubes into complex, axially symmetric parts. The technique has been employed for centuries, but with modern advancements, it has evolved into a critical manufacturing process for a wide range of industries. China has emerged as a global leader in metal spinning services, driven by its advanced manufacturing capabilities, competitive pricing, and strategic emphasis on innovation and quality control. This article explores the evolution of China’s metal spinning industry, highlighting the technological advancements, key players, and the factors contributing to its global prominence.

Historical Background

Metal spinning has ancient origins, with evidence of its practice dating back to ancient Egypt and Greece. Traditionally, it was a manual process requiring significant skill and craftsmanship. With the advent of the Industrial Revolution, metal spinning was mechanized, leading to increased production capacity and consistency. In the mid-20th century, as global manufacturing began to expand, China started to develop its metalworking industries, initially focusing on simple, low-cost products. However, over the past few decades, China has transformed its manufacturing sector, including metal spinning, into a sophisticated, high-tech industry capable of producing complex components for various sectors such as aerospace, automotive, and medical equipment.

Technological Advancements

CNC Metal Spinning

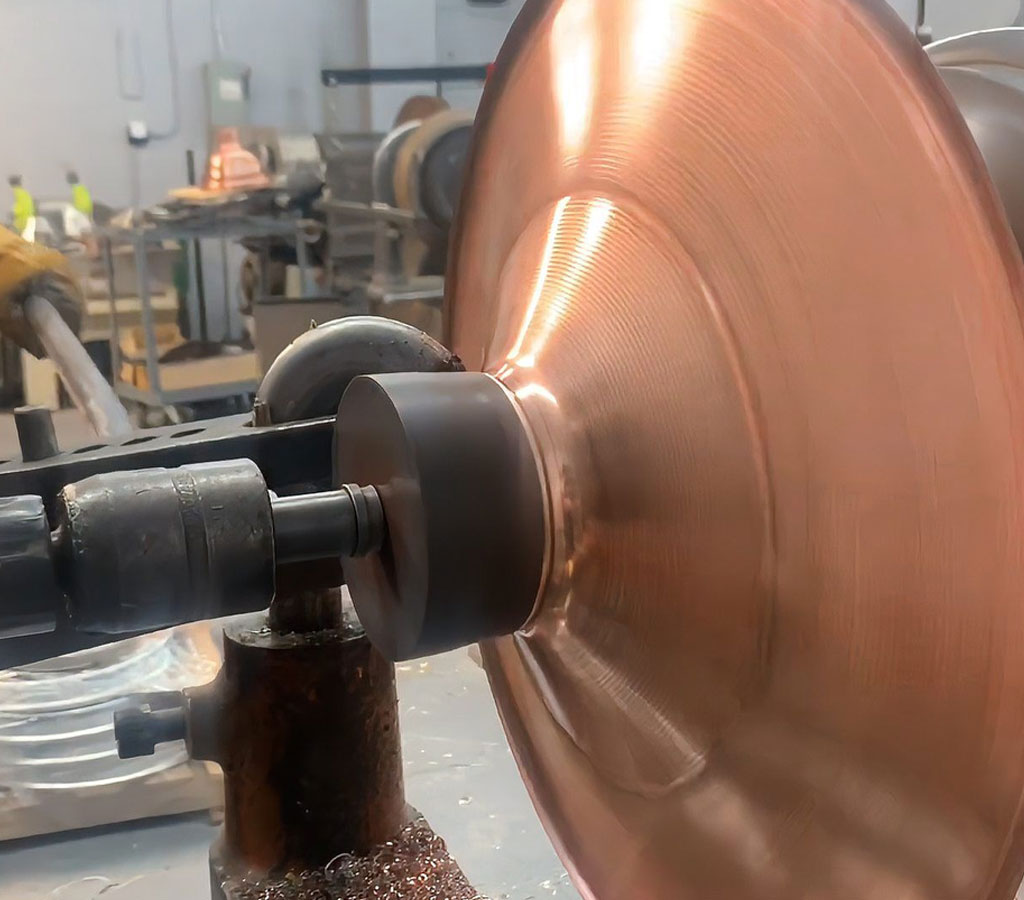

One of the most significant advancements in China’s metal spinning service is the adoption of Computer Numerical Control (CNC) technology. CNC metal spinning allows for precise control over the spinning process, enabling the production of highly accurate and consistent parts. This technology has revolutionized the metal spinning industry by reducing human error, increasing production speeds, and allowing for the mass production of complex geometries that were previously difficult or impossible to achieve with traditional methods. Chinese manufacturers have heavily invested in CNC technology, making them competitive on the global stage.

Material Innovations

China’s metal spinning industry has also benefited from advancements in material science. The ability to spin a wide range of materials, including aluminum, stainless steel, titanium, and specialized alloys, has expanded the application of metal spinning in various industries. Innovations in materials have led to the production of stronger, lighter, and more durable components. Chinese parts manufacturers have developed proprietary alloys and techniques that enhance the properties of spun metals, making them suitable for high-performance applications.

Automation and Robotics

In addition to CNC technology, automation and robotics have played a critical role in advancing China’s metal spinning services. Automated systems have been integrated into production lines, reducing labor costs and improving efficiency. Robotics, in particular, have been employed to handle repetitive tasks, ensuring consistent quality and reducing the time required to produce each part. These advancements have allowed Chinese cnc machining online manufacturers to meet the increasing demand for metal spun products while maintaining competitive pricing.

Key Players in the Industry

Several key players have emerged in China’s metal spinning industry, ranging from small specialized firms to large multinational corporations. Companies such as Dongguan BE-CU Metal Spinning Co., Ltd., Shandong Jingyanggang Metal Spinning Co., Ltd., and Suzhou Metal Spinning Manufacturing Co., Ltd. have gained international recognition for their expertise and technological capabilities. These companies have invested heavily in research and development, focusing on improving the efficiency and quality of their metal spinning processes.

Global Competitiveness

China’s metal spinning industry has become globally competitive due to several factors:

Cost Efficiency

One of the primary reasons for China’s dominance in large metal spinning services is its cost efficiency. The combination of low labor costs, economies of scale, and advanced manufacturing techniques allows Chinese manufacturers to offer competitive pricing without compromising quality. This cost advantage has attracted a significant amount of international business, particularly from companies looking to reduce manufacturing expenses while maintaining high standards.

Quality Control

Chinese manufacturers have made substantial investments in quality control measures, ensuring that their products meet international standards. Certifications such as ISO 9001, AS9100, and TS16949 are commonly held by Chinese metal spinning companies, demonstrating their commitment to quality. Advanced testing and inspection methods, including non-destructive testing and computer-aided inspection, are employed to ensure that spun metal parts meet the stringent requirements of industries such as aerospace and automotive.

Innovation and R&D

Innovation is a cornerstone of China’s metal spinning industry. Chinese companies have established research and development (R&D) centers to explore new materials, processes, and applications for metal spinning. Collaboration with universities and research institutions has led to breakthroughs in material science and manufacturing techniques. As a result, Chinese manufacturers can produce highly specialized components that meet the unique needs of their clients.

Applications of Metal Spinning in China

China’s metal spinning services cater to a diverse range of industries:

Aerospace

The aerospace industry demands high-precision components made from advanced materials. China’s metal spinning companies have developed the capability to produce aerospace-grade components, such as turbine engine parts, missile cones, and aircraft structural components. The ability to spin high-strength, lightweight alloys has made Chinese manufacturers key suppliers to the global aerospace industry.

Automotive

In the automotive industry, metal spinning is used to produce components such as wheels, exhaust systems, and fuel tanks. The precision and efficiency of Chinese metal spinning services have made them integral to the production of high-performance and luxury vehicles. Additionally, the industry’s focus on reducing vehicle weight for better fuel efficiency has led to increased demand for lightweight spun metal parts.

Medical Equipment

The medical equipment industry requires components that meet strict hygiene and safety standards. China’s metal spinning companies produce parts such as surgical instruments, medical device housings, and implantable components. The ability to work with biocompatible materials and maintain tight tolerances has positioned Chinese manufacturers as key suppliers to the medical industry.

Renewable Energy

As the global push for renewable energy grows, China’s metal spinning industry has adapted to produce components for wind turbines, solar panels, and other renewable energy systems. The ability to produce large, complex parts with high precision is essential for the efficient operation of renewable energy systems, and Chinese manufacturers have become leaders in this field.

Challenges and Future Outlook

While China’s metal spinning industry has made significant advancements, it faces challenges such as rising labor costs, increasing competition from other countries, and the need for continuous innovation to meet the evolving demands of global markets. However, the industry is well-positioned to address these challenges through ongoing investment in technology, automation, and R&D.

The future of China’s metal spinning service looks promising, with continued growth expected in both domestic and international markets. The increasing demand for high-quality, cost-effective components across various industries will likely drive further advancements in the industry. Moreover, China’s commitment to sustainability and environmental protection is expected to lead to the development of greener manufacturing processes, further enhancing the country’s competitiveness in the global market.

Conclusion

China’s metal spinning industry has undergone a remarkable transformation, evolving from a low-cost producer to a global leader in advanced manufacturing. The adoption of cutting-edge technologies, combined with a focus on quality, innovation, and cost efficiency, has propelled China to the forefront of the metal spinning industry. As the demand for high-precision, complex components continues to grow, China’s metal spinning services are poised to play an increasingly important role in the global manufacturing landscape.

The precision CNC metal spinning machines offered by BE-CU Spinning company can provide your metal forming operation with versatility and increased capacity that will benefit your bottom line. All of BE-CU Spinning company’s standard models of metal spinning machines are designed and manufactured with heave-duty, robust designs, and the features that ensure trouble free operation.

BE-CU Metal Spinning China company also designs and builds custom metal spinning equipment for custom applications; these systems can be engineered and built to meet the requirements of specific applications. All machines are designed and built utilizing state-of-the-art CNC programming software and the latest control systems from Siemens.BE-CU Metal Spinning Company also has the flexibility to customize an inspection process that meets the needs of our customers.Be-Cu provides the highest standard of cnc machining,metal spinning and rapid prototyping service for all your needs. Contact us today to know more about what we offer!

- Sales: Bella

- Web: metal-spun.com

- Phone: +86 151 1280 7161

- Email: info@be-cu.com

- Affiliated: Be-cu Prototype

- Address: Dongguan,China

Comments