Performance Comparison Between Tracked Crushing Plant And Tire Mobile Crushing Plant

In the realm of mobile crushing equipment, the choice between a tracked crushing plant and a tire mobile crushing plant can significantly impact operational efficiency and productivity. This technical analysis aims to provide a comprehensive performance comparison of these two types of portable crushing plants, highlighting their distinct features and advantages in various applications.

1. Mobility and Manoeuvrability

1.1. Tracked Crushing Plant

Tracked crushing plants, equipped with caterpillar tracks, offer exceptional mobility and manoeuvrability in diverse terrains. These units can traverse rugged landscapes, steep inclines, and unstable ground conditions with ease, making them ideal for off-road applications. The tracks provide excellent traction, ensuring stability during operation and reducing the risk of equipment damage.

1.2. Tire Mobile Crushing Plant

Tire mobile crushing plants, on the other hand, utilize wheels for movement, which allows for quick and easy transportation on paved roads. While they may not be as versatile as tracked plants in off-road conditions, they offer greater mobility on flat surfaces and stable terrain. The ability to be towed or driven between sites makes them a practical choice for projects with frequent relocations.2. Crushing Performance and Productivity

2.1. Tracked Crushing Plant

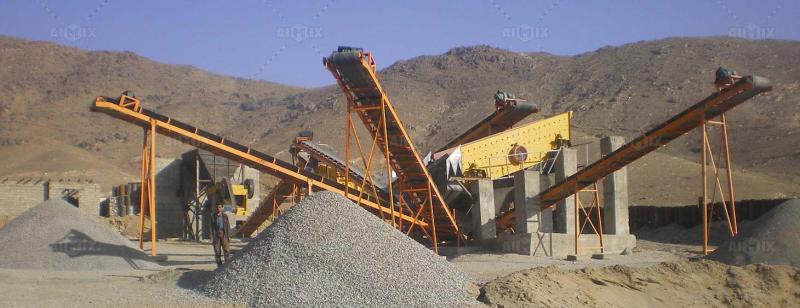

Tracked crushing plants are renowned for their robust design and high crushing performance. They typically feature a powerful crusher, a large feed hopper, and an efficient conveyor system. These plants are capable of handling a wide range of materials, including hard rocks, ores, and recycling materials. The continuous operation and high throughput capacity of tracked crushers contribute to increased productivity on the job site.2.2. Tire Mobile Crushing Plant

Tire mobile crushing plants are designed for versatility and high production rates. They offer a variety of crusher options, allowing for customization based on specific material requirements. The compact size and optimized design of these plants enhance their efficiency, resulting in faster cycle times and reduced downtime. Additionally, the mobility provided by tires enables these plants to be positioned closer to the material source, minimizing transportation time and improving overall productivity.