Take You to Learn the Structure and Working Principle of A Three-phase Alternator

The three-phase alternator is one of many generators. Its structure determines the working principle of the three-phase alternator to generate current, and its power and excitation method determine the three-phase alternator has different classifications. In this article, the generator manufacturer-Dingbo Power will give you a detailed introduction to the professional knowledge of three-phase AC generators.

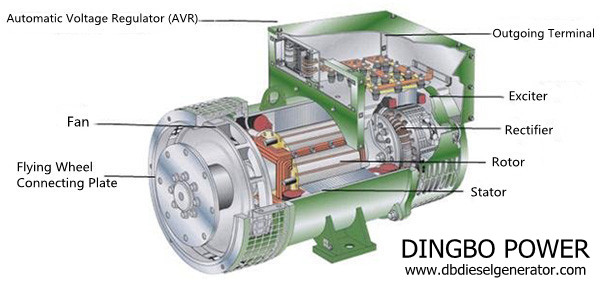

The structure of a three-phase alternator

1. The three-phase alternator is composed of stator, rotor, end cover, base, brush and bearing.

2. The stator is composed of a base, a stator core, a wire-wrapped winding and other structural parts that fix these parts. The rotor is composed of rotor iron core, rotor magnetic poles, fan, slip ring and rotating shaft.

3. The three-phase AC generator connects and assembles the stator and rotor of the generator through the frame, bearing and end cover, so that the rotor can rotate in the stator, and a certain excitation current is passed through the slip ring to make the rotor become a rotating magnetic field. The stator coil moves to cut the magnetic lines of force, thereby generating an induced electric potential, which is drawn through the terminal and connected to the loop to generate a current.

Working principle of three-phase alternator

The three-phase alternator uses the principle of electromagnetic induction, which induces electric potential by cutting the magnetic field lines, and converts the mechanical energy of the prime mover into electrical energy output. The synchronous generator consists of two parts: a stator and a rotor. The stator is the armature that generates electricity, and the rotor is the magnetic pole. The stator is composed of an armature iron core, a three-phase winding uniformly discharged, a base and an end cover, etc. The rotor is usually a hidden pole type, consisting of an excitation winding, an iron core and a shaft, a guard ring, and a ring.

The excitation winding of the rotor is energized with a direct current to produce a nearly sinusoidal distributed magnetic field (called the rotor magnetic field), and its effective excitation magnetic flux intersects with the stationary armature winding. When the rotor rotates, the magnetic field of the rotor rotates at the same time, with each revolution, the magnetic lines of force sequentially cut each phase winding of the stator, and a three-phase AC electric potential is induced in the three-phase stator winding. When the generator is running with a symmetrical load, the three-phase armature current is combined to produce a rotating magnetic field with a synchronous speed. The interaction between the stator magnetic field and the rotor magnetic field produces a braking torque. The mechanical torque input from the steam turbine overcomes the braking torque to perform work. The generator can send out active power and reactive power. Therefore, to adjust the active power, the steam intake of the steam turbine must be adjusted. The strength of the rotor magnetic field directly affects the voltage of the stator winding. Therefore, the rotor current must be adjusted to adjust the generator terminal voltage or adjust the reactive power of the generator.

Classification of excitation methods of three-phase AC generators

The generator excitation system refers to the system that supplies the generator rotor with direct current to establish the rotor excitation. It is divided into:

1. Its excitation system, its excitation is generated by an alternating current generator coaxial with the generator, which is rectified into direct current to excite the generator rotor.

2. The self-parallel excitation magnetic system is to reduce the voltage of the alternating current from the generator end through the transformer, and then rectify it into direct current, which is used as the excitation of the generator rotor.

The above is the structure and working principle of the three-phase AC generator introduced by Guangxi Dingbo Power Equipment Manufacturing Co., Ltd. We hope that the majority of users can have a better understanding of professional knowledge of the three-phase AC generator through the introduction of this article. Dingbo Power is a professional diesel generator manufacturer integrating the design, supply, debugging and maintenance of diesel generator sets. We can provide you with diesel generator sets of various specifications from 30KW to 3000KW. Welcome to consult. Please do not hesitate to contact us at dingbo@dieselgeneratortech.com.

Post Your Ad Here

Comments