How does a nitrogen generator work?

What is Nitrogen?

Nitrogen is abundant and makes up most of the air we breathe. Nitrogen is a colorless, odorless, inert gas that generally does not react with other substances. It is this characteristic that makes nitrogen widely used in many anaerobic environments to play the role of isolation, flame retardant, explosion-proof and anti-corrosion. Nitrogen is also used as a blanketing gas in the packaging of processed foods and pharmaceuticals to extend shelf life.

How does the nitrogen generator work?

Nitrogen for production can generally be obtained in three ways: bottled, liquid, and on-site nitrogen production. The first two methods rely heavily on nitrogen suppliers, which could be more efficient and affordable. So on-site nitrogen production has become the choice of many companies. This article will introduce you to how the nitrogen generator produced by Minnuo works.

PSA nitrogen generator

Pressure swing adsorption air separation (PSA) is an advanced gas separation technology. Use high-quality and high-efficiency carbon molecular sieve (CMS) as the adsorbent. Air separation is achieved by absorbing oxygen in compressed air to produce nitrogen of acceptable purity.

Working Process

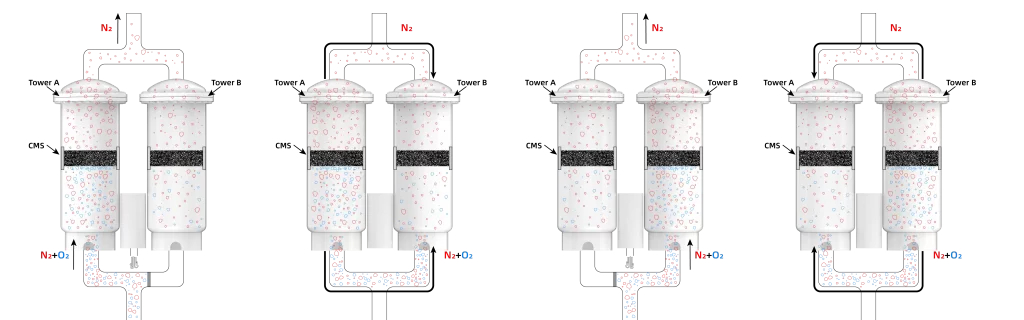

The PSA nitrogen generator has two independent containers, Tower A and Tower B. Both towers are equipped with CMS. They can switch back and forth between the separation and regeneration processes.

- First, the air stream enters Tower A through cleaning, drying, and compression. Since oxygen molecules are smaller than nitrogen molecules, they can enter the pores of the CMS and be adsorbed. However, larger nitrogen molecules cannot enter the gap of the CMS and can only bypass the CMS to leave Tower A in the form of nitrogen. Most of the nitrogen produced in Tower A leaves this system for immediate use or storage. A small portion of nitrogen enters Tower B in the opposite direction.

- At the same time, by releasing the pressure in Tower B, the CMS cannot retain the oxygen previously adsorbed by Tower B. They are separated from the CMS and carried out the vent by a small amount of nitrogen from Tower A. This way, the system can free up space for the CMS on Tower B to adsorb new oxygen molecules during the next adsorption stage. This process of “cleaning” the oxygen saturation tower is called regeneration.

- When the pressures in both towers are equalized, the switchover is initiated. Currently, the CMS in Tower A is saturated, and Tower B can restart the adsorption process due to the pressure reduction and generate nitrogen. Tower A is in the regeneration process.

Generally speaking, in the first stage, tower A is in the adsorption state, and tower B is in the regeneration stage. In the second stage, the pressure of the two towers is balanced, ready to switch each other. In the third stage, tower B is in the adsorption stage, while tower A is regenerating. In the fourth stage, the two towers began to prepare for a new switch. This cycle is repeated, and the double-tower PSA system continuously produces nitrogen of the required purity.

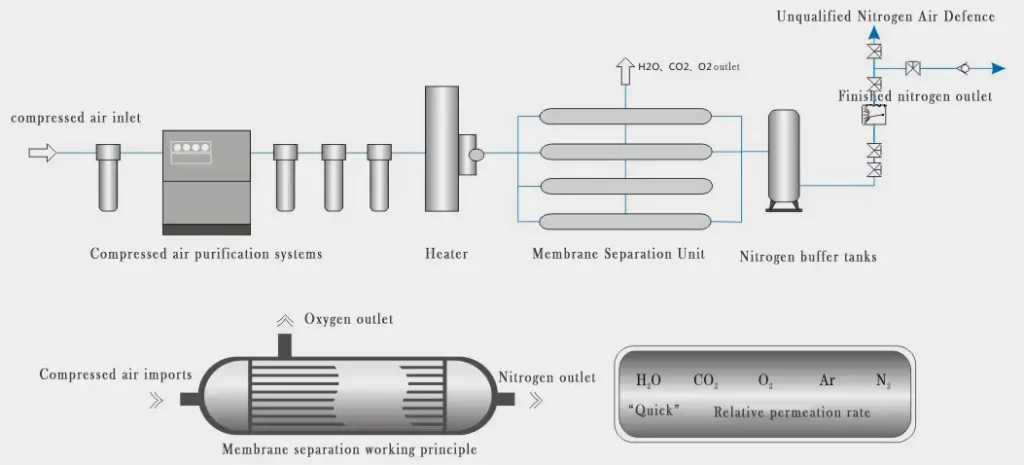

Membrane Nitrogen Generator

Minnuo Membrane Nitrogen Generator uses membrane separation technology: clean and dry compressed air enters one or more membrane modules, the gas components with faster permeation rates (e.g. H20, H2, O2, etc.) are enriched on the low-pressure permeation side by preferentially passing through the membrane wall, while the gas components with relatively slow permeation rates (e.g. N2, etc.) are enriched on the high-pressure stagnation side, thus obtaining the required purity of nitrogen gas.

Woking Process

- The compressed air from the air compressor enters the air buffer tank and then enters the multi-stage filter, including the activated carbon filter, which removes particles, oil and water from the air.

- The clean air enters the membrane for oxygen and nitrogen separation. Generally speaking, the imported filters can remove the particles in the air to <0.01um and oil to <0.01ppm, which can fully meet the requirements of the membrane for air quality.

- Stable quality suction dryers and cold dryers can treat the water in compressed air to the dew point of -20 to -60℃.

- Temperature heating and control in the middle of the filter – to ensure that the membrane works under optimum conditions

- Constant temperature, clean air then enters the membrane for separation, qualified product gas goes to the next process, unqualified product gas is automatically discharged

Conclusion

In general, the working principle of the nitrogen generator is: to separate the nitrogen molecules in the compressed air from the oxygen molecules to produce pure nitrogen. Minnuo provides PSA nitrogen generator and membrane nitrogen generator to ensure nitrogen supply. What kind of nitrogen generator to use in your work depends on the nature of your work and the quality of nitrogen you need. For example, when low-purity nitrogen below 99% is required, it is sufficient to choose a membrane nitrogen generator. If you need nitrogen with 99.999% purity or extremely high purity, you should choose a PSA nitrogen generator.

If you want to get the best solution for on-site nitrogen production, please contact us! We can customize it for you!

Post Your Ad Here

Comments