Five Common Types of Fiber Optic Cables

Fiber optic cables refer to cables containing one or more optical fibers that are used to carry light. They are widely used in the Internet, telephone systems, cable TV, etc. There are various fiber optic cables based on different classification standards, such as single mode and multimode optical fiber cable according to fiber core size. And they can be terminated at both ends with the same or different fiber optic connectors to form fiber optic jumper cables, like LC to LC fiber cable, ST to LC patch cable. It is crucial to choose fiber optic cables carefully as the choice will affect the installation, termination and also the cost. This paper will introduce five commonly used fiber optic cables and their own special applications, including: tight buffer cables, loose tube cables, ribbon cables, armored cables and aerial cables.

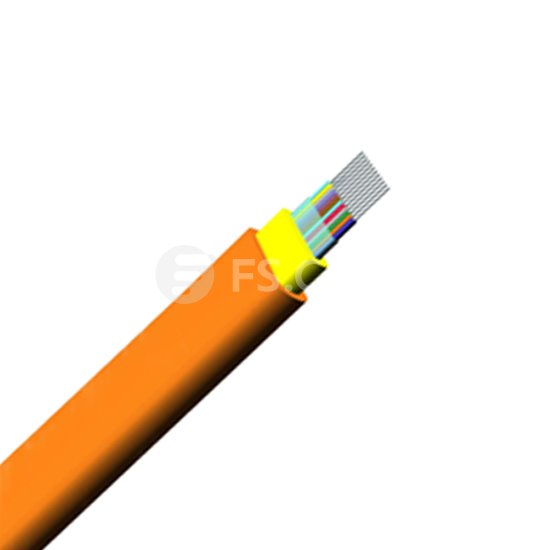

Generally, tight buffer cables are used indoors where cable flexibility and ease of termination are important to satisfy the diverse requirements existing in high performance fiber optic applications. In tight buffer cables, each buffer has one fiber to ensure excellent mechanical and environmental protection. Besides, there are no needs for gel filling, cleaning and stiff strength member for tight buffer cables. They are also easy to terminate with no breakout kits or splicing required. Simplex and zip cord, distribution cables and breakout cables all belong to tight buffer cables.

Loose tube cables are the most widely used cables for outside plant trunks because they offer the best protection for the fibers under high pulling tensions and can be easily protected from moisture with water-blocking gel or tapes. These cables are composed of several fibers together inside a small plastic tube. Unlike tight buffer cables, gel filling, cleaning and stiff strength member are all needed in loose tube cable constructions. In addition, loose tube cables are difficult to terminate and breakout kits and splicing are required.

Ribbon cables are preferred where high fiber counts and small diameter cables are needed. These cables have the most fibers in the smallest cable, since all the fibers are laid out in rows in ribbons, typically of 12 fibers, and the ribbons are laid on top of each other. Ribbon cables deliver the highest fiber density in the most compact cable package possible. In addition, streamlining fiber termination used for ribbon cables can save time and money with easy mass-fusion splicing.

Armored cables are deployed in direct buried outside plant applications where rugged cables are needed and/or rodent resistance. These cables withstand crush loads well. There are mainly two applications for armored cables. One is that they can be directly buried in areas where rodents are a problem. Because they have metal armoring between two jackets to prevent rodent penetration. The other application of armored cables is in data centers, where cables are installed underfloor and one worries about the fiber cable being crushed. Because armored cables are conductive, they must be grounded properly.

Aerial cables are for outside installation on poles. They can be lashed to a messenger or another cable, common in CATV, or have metal or aramid strength members to make them self supporting. These cables have steel messengers for support. Like armored cables, they also must be grounded properly. OPGW (Optical Power Ground Wire), which is a high voltage distribution cable with fiber in the center, is one of the widely used aerial cables. In aerial cable constructions, fibers are free from being affected by the electrical fields. These cables are usually installed on the top of high voltage towers but brought to ground level for splicing or termination.

Actually, there are more complicated fiber optic cables types except the above five fiber cables because every manufacturer has its own specialties and sometimes their own names for common cable types. Various material combinations and layers are used to create cables that meet the demands of the customers' application on the casino floor, in the windmill, across the factory’s automation network, tethered to robots, or throughout the oil field.

Comments