Facts And Facets To Learn About Printing Shipping Labels

Shipping labels get created during the processing of any order. Printing these labels include two comprehensive options. One is the standard laser or inkjet labels printer, while the other is the thermal label printing process. Here’s your guide to learning the facts & facets of printing Shipping/Freight Labels. Let’s delve into the narration below.

1. Laser or Inkjet Printing

Avoiding the inkjet printing process for a truckload of labels is predominant. But if you are about to print just a few labels each month, this printing solution can benefit you. Only be careful enough to ensure that everything on the sheet is crystal clear. Additionally, it is important to make sure that the paper is smudge-free.

Laser printers can offer yield quality labels with high precision, unlike inkjet printers. But it can turn out to be expensive with costly label sheets & toner cartridges. As a matter of fact, this is never a very good option when it comes to printing an adequate amount of labels every month.

2. Thermal Label Printing

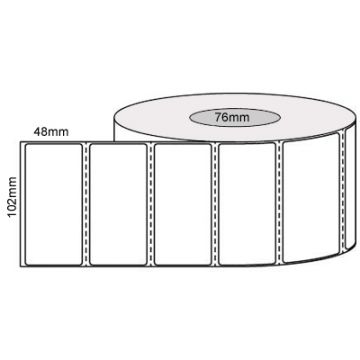

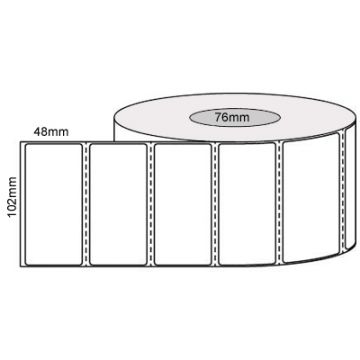

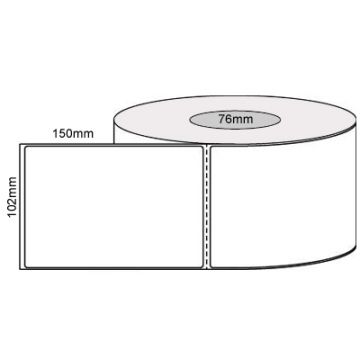

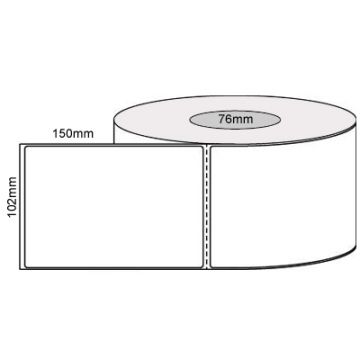

Direct Thermal label printing makes the best option. In fact, they do not require additional supplies such as ink, toner, or something else. The only thing is that it requires labels rolls. The printers will work by making shapes on papers using heat. It enables accurate and long-lasting labels. Nonetheless, they are costly devices. When it is about printing a considerable amount of labels, it’s great to invest in it.

Creating Shipping Labels: What Should You Know?

Creating shipping labels would require you to follow the carrier requirements. For this reason, you need to do either of the two:

• Visit the local post office & pay for it

• Arrange your label

If you have DYMO printer-compatible labels, you need to understand that Dymo Labels comprises a cut between the two labels.

What Do You Understand by Thermal Transfer Labels?

Thermal-transfer printing happens to be a digital printing method. Here, the material gets applied to the by melting the ribbon coating. This way, it stays glued to materials where the print gets applied.

Direct thermal printing needs to print head elements in direct contact with label material. On the other hand, thermal transfer printing comprises the thermal ribbon that acts as the “buffer” between the label material and print head elements. Retailers can learn about Retail Labels for creating labels in small quantities.

Advertise on APSense

This advertising space is available.

Post Your Ad Here

Post Your Ad Here

Comments