Common Sewing Machine Problems and Remedies

The process of sewing is a successful and rewarding activity. However, it entails particular issues that are part of it. Whether it’s a complete novice or an expert’s experience, sewing machine-related problems are irritating and a big no. Nonetheless, learning some of these basics allows you to fix many issues without asking for help. In the remaining parts of this writing, we will learn the most common problems in a sewing machine and the simplest possible solution to make your stitching experience as easy as possible.

Content Explore: best sewing machine for experienced sewers

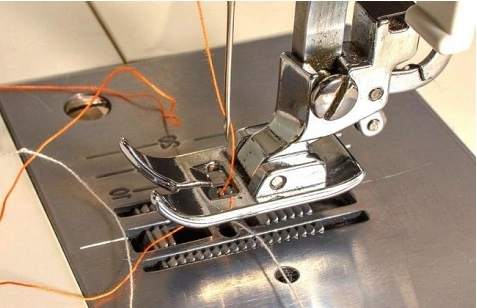

Problem 1: Thread Breakage

This is one of the sewists' most recurrent problems, and threads break often. This can happen when the needle is not sharp enough, the thread is of lousy quality and wrong, the numbers and the types of threads are wrong, or when everything is done wrong.

Remedy: Open with the fact that the thread you will use must be of good quality that can match your fabric and needle. Next, we must re-thread the machine, always following the correct threading path described in the machines' manuals. More importantly, look for any spots or rips on your needle tips and replace them if you find them.

Problem 2: Uneven Stitching

For example, if you see separate sides of the stitch being different, long or short, it might mean that your stitching is not tight and even.

Remedy: Plaiting mistakes come as a result of wrong preset tension. Start by adjusting the tension dial on your sewing machine; make minor adjustments after each pass until a stitch looks balanced on both sides. Secondly, pay attention to the machine being threaded correctly and the bobbin in the correct position.

Problem 3: Skipped Stitches

Minor errors, such as skipped stitches where the machine doesn't catch the fabric, can cause the seam to be weak and compromise the production of the item of clothing.

Remedy: If the needle is worn out or bends due to inappropriate handling, skipped stitches are often the outcome. Wash the needle holder and ensure it is clean and undamaged, then use it to replace a new sharp needle appropriate for the fabric type you're sewing. Furthermore, please pay attention to the positioning of the needle and use it based on your sewing machine's guide.

Problem 4: Jammed Bobbin

A jammed bobbin happens when the thread gets all tangled up or firmly stuck in the bobbin box, which hinders the machine's smooth operation.

Remedy: Start with withdrawing the bobbin case carefully and untwisting all the lines of thread that are kinked around the bobbin perimeter. Squeeze the bobbin area and see if it is free of loose threads or other objects that might obstruct the mechanism. Clear it up if there is any. Next, put the bobbin back in place and check the machine, hoping it will run smoothly.

Problem 5: Noisy Operation

Those who have experienced excessive noise during sewing can tell that it's very annoying and could also be a sign that your machine has major or minor defects.

Remedy: First of all, do a thorough safety inspection of the machine and then tighten all the loose screws and parts into place. To lower the level of “friction” and avoid unnecessary noise that accompanies the work of sewing machine components, apply sewing machine oil. If you notice any of these noises, you may have an internal problem with your machine; thus, plan for it to be serviced by an expert professional.

Conclusion

Knowing the top issues and solutions pertaining to sewing machines, you will be able to go through these problems and look for a solution as they occur. You should sometimes clean and oil your machine regularly to stay operable, and do not hesitate to ask for the help of a professional when you encounter a more severe problem. You will surely be at ease with your sewing machine smile in a few days of hearts and figuring out.

Post Your Ad Here

Comments