Appliacation of biomass pellet press and biomass pellet

Biomass pellet fuel refers to the crushed corn, wheat, cotton, rice, wheat and oil crops, sawdust, straw, leaves and other agricultural and forestry waste added into the biomass pellet press machine, the crushed material is pressed against the roller and die and form the material into solid state biomass pellets. Biomass pellet fuel can be used in special stove cooking heating, thermal power generation, biomass industrial boilers and so on. Biomass pellet fuel has the characteristics of easy transportation, easy storage and high combustion efficiency. Promoting the use of biomass pellet fuel is a good project for developing a "low-carbon economy".

Development prospects biomass pellet fuel

From the characteristics of straw pellet fuel, there are the following aspects:

- Using the wastes (crop stalks, rice husks, peanut shells, corn cobs, sawdust, twigs, leaves and wood trim etc.) used in agriculture and forestry as raw materials, environmental protection and energy saving, safety, good for fire prevention.

- High density and long burning time. The straw is crushed and processed into a compact shape, and the volume of the pellet fuel is reduced by 4 to 6 times, greatly prolonging the burning time of the straw.

- Convenient in combustion, storage and transportation.

- Biomass pellet fuel diameter is generally 4mm, 6mm, 8mm, length of 10 ~ 20mm, the density of the biomass pellet fuel is no less than 1100kg / m3, ash content is no more than 0.9%, calorific value is not less than 14,650,500.

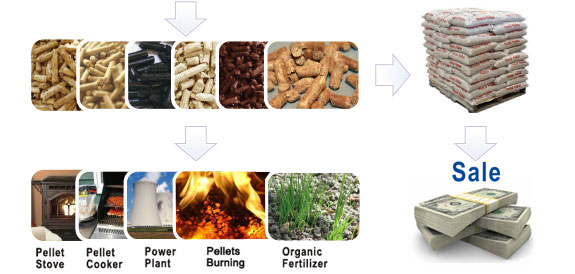

Application of biomass pellet fuel

From the application situation, biomass solid fuels technology and equipment have matured in many countries, forming a sound industrial chain system. As in South Korea, Japan, the government provides free fuel for residents cooking, heating use. China's biomass solid fuels industrialization of key technologies also become mature. Recently, Natural Resources Canada has awarded $6.45 million to support six projects in British Columbia that aim to promote innovation and diversification in forestry and support collaboration with Indigenous communities. Several of the projects address bioenergy.

From the use of view, biomass pellet fuel has a wide

range of applications, it can replace wood, liquefied petroleum gas,

etc., it is widely used in biomass straw power generation plants,

enterprises boilers, biomass straw gas station, household gasifier,

European-style heating Fireplace and so on.

The formed biomass pellet fuel also has good combustion performance

similar to that of briquette, and has the advantages of small sulfur

content, less ash and less environmental pollution than coal. Compared

with firewood, biomass pellet fuel has low moisture content and large

specific gravity and calorific value, which is beneficial to improve the

thermal efficiency of biomass pellet fuel stoves.

Therefore, biomass pellet fuel is widely used in biomass straw power

plants, factory and institution boilers, biomass fuel gasification

stations, household heating stoves for cooking, European-style heating

fireplace, and replace coal, to solve environmental pollution problems.

The biomass fireplace is made to burn biomass pellets. The product uses

advanced control technology, automatic ignition, automatic feeding,

with the advantages of energy saving, environmental protection, clean,

safe, convenient, etc., is an ideal heating equipment for home, office

space, public places and so on.

production process biomass pellet fuel

Biomass pellet fuel production process is: raw material recovery →

crushing (powder length less than 5mm) → quenching and tempering

(moisture content less than 15%) → press molding → output cooling and

drying → packaging and transportation.

biomass pellet pelletizing premise

- smash the raw material unit density as possible

- The higher the unit density of pulverized raw materials, the better the self-flowability and the higher the granulation yield. The crop stalks are best crushed into granules with a crusher; pulverized raw materials obtained by crushing with a kneading machine have more filaments, easy overhead, with poor feeding performance and low granulation yield.

- material moisture content should be appropriate

- Material moisture content too high or too low will affect the yield and quality of granulation. If the moisture of material is more than 20%, the quenching and tempering will be difficult, it may cause plugging of the die wholes, reduce production; also easy to cause pellet expanding.

why choose TICO pellet press machine?

- Simple structure, scientific and reasonable design, low noise, occupies less space.

- Powder feed, grass powder without (or a little) liquid can be added for granulation. Therefore, the moisture content of pellet after pelletizing is almost the same to the moisture content of material before, makes pellets more conducive to storage.

- Pellets processed by this pellet machine have smooth surface, not easy to break and highly cooked. Improved nutritive quality of feed,easy digestion and absorption. The degree of internal maturity is more adequate, can improve the digestion and absorption of nutrients, but also kill the general pathogenic microorganisms and parasites, suitable for feeding rabbits, fish, ducks and laboratory animals. get higher economic benefits than the mixed powder feed.

- Equipped with variety size of die aperture from Ø1.5 to Ø20 to adapt to different materials granulation and achieve the best results.

- Adapt to different materials and ensure suppression effect. Compression molding of sawdust, corn stalks and other materials needs a lot of pressure. Roller parts are the central components of the entire equipment, and the use of high-quality alloy steel can improve the service life of the roller.

Comments