Why is an EPS Panel Better Than Traditional Construction?

Pre engineered buildings are one of the most advanced construction technologies in modern times. These structures can fulfil our need for efficient, sustainable, and cost-efficient buildings. EPS panels, a component of these structures, have a significant role.

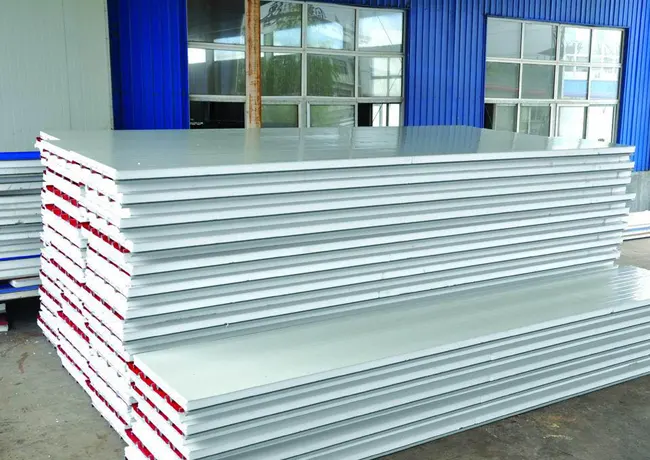

Expanded Polystyrene Panels (EPS) have become crucial in modern building construction. They offer numerous advantages in a PEB building, as their main role is to provide superior thermal insulation, ensure energy efficiency, and maintain a comfortable indoor environment.

As you read the article further, you’ll find out why EPS Wall Panels are better than conventional options and whether you should make a purchase decision.

Offering Thermal Efficiency

EPS panels are known for their great insulation. They are made of closed cells that trap air, keeping heat from easily passing through. This means less energy is wasted on heating and cooling a building.

Older building methods, like using brick or concrete, don't insulate as well. This leads to higher energy bills and is not eco-friendly.

EPS panels are different. They help keep the temperature inside steady, so you don't need as much heating or air conditioning. This saves money and is better for the environment.

Speed of Construction

If you have a short timeline for a manufacturing facility, its highly suggested to consult an EPS Panel Supplier to get an estimate of the time by which it will be complete.

However, these panels usually outperform traditional methods, since they are manufactured in factories with precision and quality control. Further, they are transported on site, where the only time taken is in the assembly of these components.

In traditional construction methods, there are multiple stages, from site preparation to bricklaying and concrete pouring; every task is tedious and time-consuming. The second stage can't begin until the task of the first stage is completed.

With EPS Panel Construction, this isn’t the case at all. Different components are built in factories simultaneously, which saves time. For large-scale projects, this is particularly important.

Structural Integrity

Despite their lightweight nature, EPS panels provide excellent structural integrity. The panels consist of an EPS core sandwiched between two layers of structural materials, such as galvanized steel or cement board. This combination results in a strong, durable, and rigid construction material.

Traditional building materials, like bricks and concrete, are known for their strength, but they are also heavy and require substantial foundational support. EPS panels offer a comparable level of strength while being much lighter. This characteristic can reduce the load on foundations and lower the overall structural costs.

Furthermore, EPS panels are resistant to seismic activity due to their flexibility and ability to absorb and dissipate energy. This makes them a suitable choice for construction in earthquake-prone areas, providing an added layer of safety and resilience.

Impact on Environment

Given that the construction sector is one of the major contributors to carbon emissions, introducing sustainable practices becomes quite important. EPS Sandwich Panels and such components together make a big difference over traditional construction this way:

ENERGY EFFICIENCY: EPS PANELS have high thermal insulation properties. This reduces energy consumption, usually wasted on heating and cooling due to the ever-changing weather.

MATERIAL EFFICIENCY: These panels create far less waste than traditional construction methods. Moreover, EPS panels are made from recycled materials, which further enhances their sustainability.

LESS RESOURCE CONSUMPTION: In traditional construction, limited resources, such as water, are used extensively for concrete mixing and curing. EPS panel manufacturers provide them prefabricated, which reduces water consumption on-site and saves this valuable resource.

RECYCLE: EPS Sandwich Panels can be recycled, and when they are scraped, they can be repurposed to make new material. This is quite the opposite of traditional construction debris, which can never be reused. It ends up being in landfills and contributes to environmental degradation.

Versatility

EPS Panel Manufacturers, on-demand, can make components for different types of industries to cater to their needs, whether it's a sports complex or commercial building. The adaptability of PEB and Prefab components ranges to different spectrums.

For example, these can be made in different designs, cuts, and finishes. They can also suit different floors, roofs, and wall requirements.

Even if traditional construction methods can offer diversification, there is still a need for different materials and techniques for different use cases. With EPS panels, one gets a unified solution which simplifies construction for every industry. Thus, one can ensure consistency and quality across the building.

Conclusion

EPS panels offer far more advantages than traditional construction. They offer superior thermal efficiency, save money on energy, are rapidly constructed, and have high structural integrity. Besides, they are environmentally friendly and flexible, which makes them good for nature and builders likewise.

The construction industry is evolving rapidly, and EPS Panels, as part of prefab/ PEB technology, can enhance the level of innovation in this industry. EPACK Prefab, one of the most trusted EPS Panel Manufacturers, can significantly help harness this technology's benefits. Consult an expert if you use EPS panels for your next PEB project.

Post Your Ad Here

Comments