Worley Machine Enterprises: A Leader in Large-Scale CNC Precision Machining for Global Industries

In today’s rapidly evolving

industrial landscape, precision and accuracy are more critical than ever,

particularly when it comes to manufacturing complex components. For companies

in need of large-scale CNC machining services, Worley Machine Enterprises

stands out as a leader in the field. With a reputation for delivering

high-quality components that meet exact blueprint specifications, Worley

Machine Enterprises serves industries worldwide, providing the expertise and

technology required for even the most demanding projects.

Precision and Reliability at the

Core of Worley Machine Enterprises

Worley Machine Enterprises has built

its success on a foundation of precision, reliability, and customer-focused

service. As a full-scale CNC (Computer Numerical Control) machine shop, the

company specializes in producing custom components to meet the unique needs of

each client. Whether it’s a small batch run or large-scale production, they are

equipped to handle projects of varying sizes and complexities with unmatched

accuracy.

Key elements of their service

include:

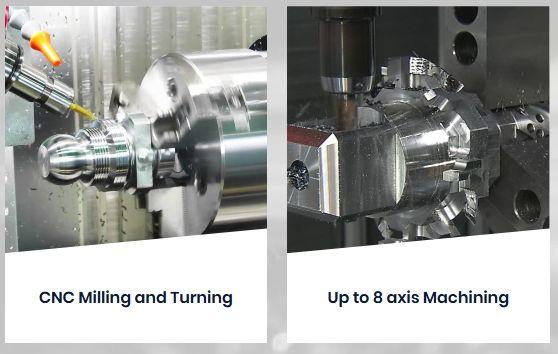

1. Advanced CNC Machining

Capabilities

At the heart of Worley Machine

Enterprises’ operation is their state-of-the-art CNC machinery. These advanced

machines can produce highly complex parts with tight tolerances, ensuring that

every component matches the exact specifications outlined in client blueprints.

Their capabilities include turning, milling, drilling, and grinding, allowing

them to produce parts with intricate geometries and precise dimensions. This

makes them a preferred choice for industries such as aerospace, automotive, oil

and gas, medical, and heavy machinery.

2. Large-Scale Production

Capacity

Worley Machine Enterprises is

uniquely positioned to handle large-scale production orders, making them a

valuable partner for companies that require high-volume manufacturing. Their

facility is equipped with high-capacity CNC machines that can operate around the

clock, meeting tight deadlines without sacrificing quality. This capability is

particularly important for industries that require a consistent supply of

precision components, enabling them to maintain efficient production lines and

meet market demands.

3. Blueprint-Driven

Manufacturing

One of the distinguishing factors of

Worley Machine Enterprises is their meticulous approach to blueprint-driven

manufacturing. They work closely with clients to fully understand the

specifications and requirements of each project, ensuring that every detail is

accounted for during the machining process. From initial design consultation

through to final production, their team is committed to delivering parts that

match the client’s vision with pinpoint accuracy.

4. Commitment to Quality

Assurance

Quality is paramount at Worley

Machine Enterprises, and their rigorous quality assurance processes ensure that

each component leaving their facility meets the highest standards. They utilize

advanced inspection equipment and quality control methods to verify that each

part aligns with blueprint specifications, including precision measurements,

surface finishes, and material integrity. This commitment to quality has earned

them a reputation for delivering components that not only meet but often exceed

client expectations.

5. Global Reach and Industry

Expertise

While based in the United States,

Worley Machine Enterprises has a global reach, serving clients across multiple

continents. Their ability to manufacture and ship precision components worldwide

makes them an ideal partner for companies looking for a reliable supplier that

understands international standards and requirements. Their extensive industry

knowledge allows them to adapt to the specific needs of each market, offering

solutions that align with diverse regulatory environments and performance

criteria.

How Worley Machine Enterprises

Supports Key Industries

The expertise of Worley Machine

Enterprises extends across a variety of sectors, where precision, durability,

and consistency are non-negotiable. Here are some of the industries they serve

and how their CNC precision machining services make a difference:

·

Aerospace: The aerospace industry

requires components with extremely tight tolerances and complex geometries to

ensure safety and performance. Worley Machine Enterprises’ CNC precision

machining capabilities make them a trusted supplier for aerospace parts,

including custom fittings, engine components, and structural elements that meet

strict aerospace standards.

·

Automotive: Automotive manufacturers

depend on precision machining for everything from engine parts to transmission

components. Worley Machine Enterprises offers large-scale production capacity,

allowing them to support automotive clients with high-volume runs of precision

parts that keep vehicles running smoothly.

·

Medical

Devices:

In the medical industry, precision is critical to the function of devices and

implants. Worley Machine Enterprises’ ability to produce complex components

with exact specifications makes them a valuable partner in the production of

medical equipment, surgical instruments, and prosthetic parts.

·

Oil

and Gas:

Components for the oil and gas industry must withstand extreme conditions and

stresses. Worley Machine Enterprises provides durable, high-precision parts

that are essential for equipment reliability and efficiency, such as valves,

drilling components, and pipeline parts.

·

Heavy

Machinery and Industrial Equipment: For industries that rely on heavy

machinery, Worley Machine Enterprises delivers the robust components needed to

ensure operational efficiency. Their ability to produce large parts with

precision helps industrial clients maintain uptime and extend the lifespan of

their equipment.

The Worley Machine Enterprises

Advantage

Partnering with Worley Machine

Enterprises offers several key advantages:

·

Tailored

Solutions:

Worley Machine Enterprises takes a collaborative approach, working closely with

clients to provide tailored machining solutions that align with their specific

requirements. This includes custom material selection, surface finishes, and

specialized processes to meet the unique demands of each project.

·

State-of-the-Art

Technology:

Their investment in cutting-edge CNC technology allows them to stay at the

forefront of the machining industry. This commitment to innovation ensures that

clients benefit from the latest advancements in precision manufacturing,

resulting in better quality and faster turnaround times.

·

Dependable

Delivery:

Timely delivery is crucial in today’s fast-paced industries, and Worley Machine

Enterprises has built a reputation for meeting deadlines without compromising

quality. Their efficient production processes and logistical expertise enable

them to deliver components when and where they are needed, keeping client

projects on track.

Trust Worley Machine Enterprises for

Your Precision Machining Needs

Worley Machine Enterprises is more

than just a CNC machine shop; they are a strategic partner for companies around

the world seeking precision, reliability, and excellence in manufacturing. With

a focus on delivering components that meet exact blueprint specifications, they

have earned the trust of clients across a variety of industries. Their

combination of advanced technology, experienced craftsmanship, and unwavering

commitment to quality makes them the ideal choice for large-scale CNC precision

machining.

Precision CNC Machining& Contract Manufacturing in Virginia:When precision matters, choose Worley Machine Enterprises - where your vision meets unparalleled machining expertise. Contact them today to learn how they can support your next project with precision components delivered to the highest standards.

Comments (1)

Boston Fire & Flood

6

Such a Nice approach sir